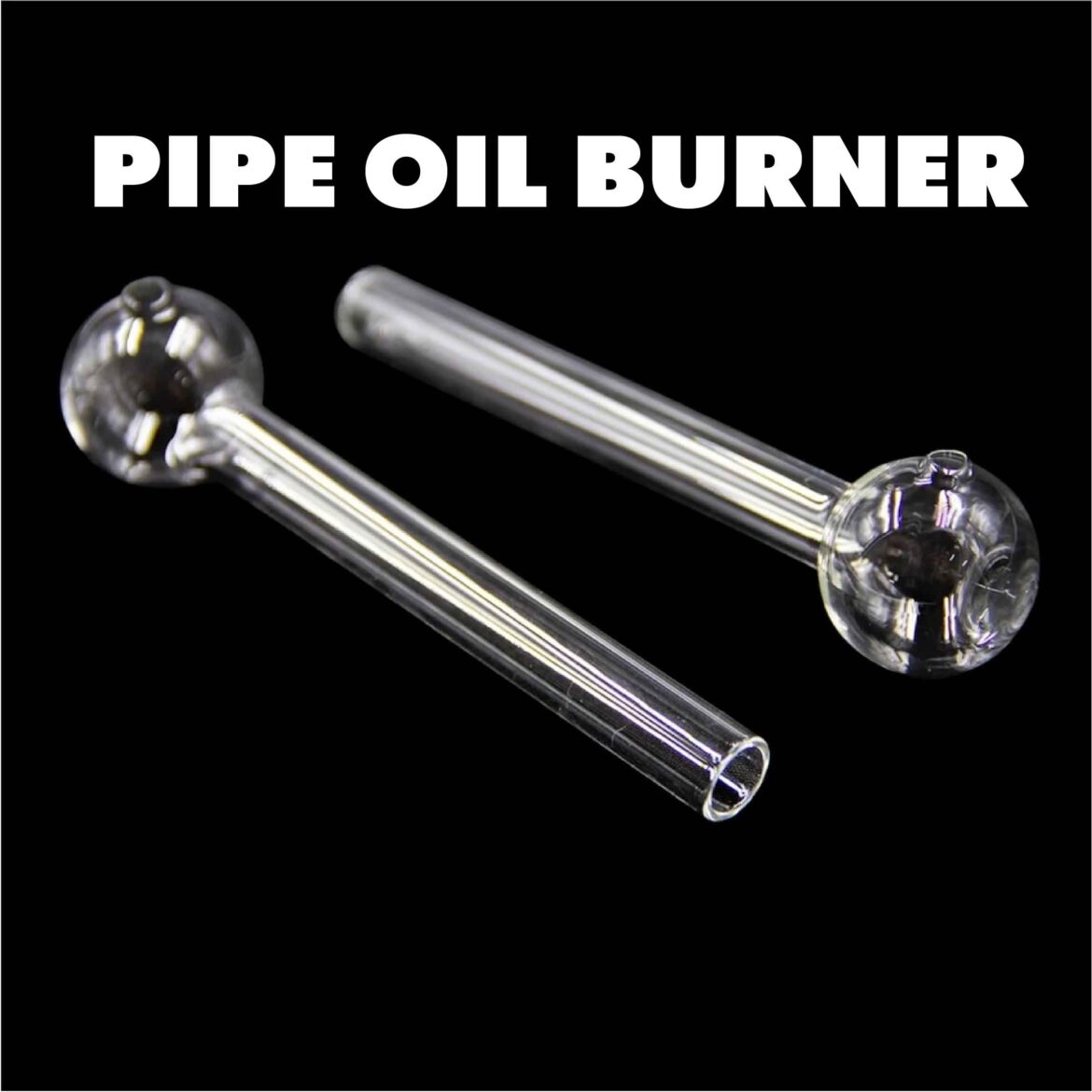

Understanding Pipe Oil Burners

The realm of heating systems is both vast and varied, encompassing a range of technologies designed to meet our warmth and industrial needs. Among these, the pipe oil burner stands out as a pivotal component, especially in contexts where precision, efficiency, and reliability are paramount. This article embarks on an exploration of pipe oil burners, shedding light on their operation, benefits, and the essential know-how for their optimal use.

The Basics of Pipe Oil Burners

At its core, a pipe oil burner is a device that efficiently converts oil into heat through the process of combustion. This simple yet effective mechanism is at the heart of many heating systems, from domestic boilers to industrial furnaces. Understanding how it works is the first step toward appreciating its value in our daily lives.

Types of Pipe Oil Burners

Delving deeper, we encounter a variety of pipe oil burners, each designed with specific applications in mind. From the compact models suitable for home heating to the robust versions powering industrial operations, the diversity within this category is impressive. Exploring these types helps potential users make informed decisions tailored to their unique needs.

Benefits of Using Pipe Oil Burners

The advantages of employing pipe oil burners are manifold. Efficiency, reliability, and the capacity to utilize a variety of oil grades stand out as primary benefits. These features not only make them a versatile solution for heating needs but also underscore their role in promoting sustainable energy use.

Key Components of Pipe Oil Burners

Understanding the anatomy of a pipe oil burner illuminates the ingenuity behind its function. Key components include the burner nozzle, which plays a crucial role in fuel atomization; the fuel supply system, ensuring a steady flow of oil; and the ignition system, responsible for initiating the combustion process. Each part is a testament to the precision engineering that pipe oil burners represent.

Installation Process

Installing a pipe oil burner is a task that demands attention to detail. This section offers a step-by-step guide, emphasizing the importance of correct installation for safety and performance. While professional installation is recommended, understanding the process provides valuable insights into the burner’s operation.

Maintenance and Safety Tips

Maintaining a pipe oil burner in top condition is vital for its longevity and safe operation. This segment offers a maintenance checklist and highlights safety precautions, ensuring users can enjoy the benefits of their burner without compromise.

Common Issues and Troubleshooting

Even with meticulous maintenance, issues can arise. Recognizing common problems and knowing how to address them empowers users to manage their systems effectively, minimizing downtime and ensuring continuous operation.

The Future of Pipe Oil Burners

Innovation in the field of pipe oil burners promises even greater efficiency and environmental friendliness. This section speculates on future trends, reflecting on how upcoming technologies could further enhance the performance and sustainability of these essential devices.

Conclusion

Reflecting on the journey through the world of pipe oil burners, it’s clear that their role extends beyond mere utility. As custodians of warmth and drivers of industrial processes, they are a testament to human ingenuity and our quest for efficiency. As we look forward to the innovations that will shape their future, the importance of understanding, maintaining, and safely operating these devices remains paramount.